Best Rated Band Saws

20 Inch Band Saws

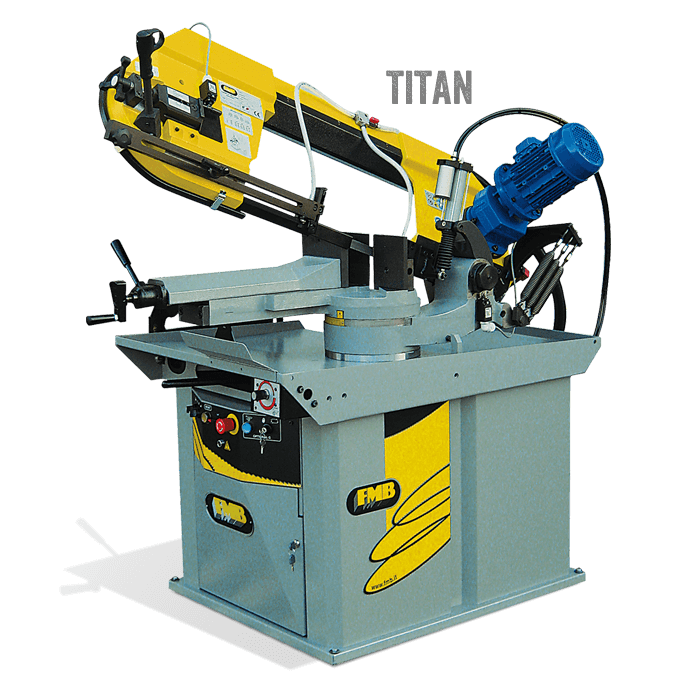

This saw is driven using an electricmotor. It has a pulley, belt and drive. It makes it easy to adjust speed or make adjustments.

For easy blade movement, a cast aluminum stand is included with cast aluminum wheels and rubber tires.